Offset Printing Inks

Offset printing is a widely-used commercial printing technique where an image is transferred from an aluminium plate to a rubber blanket and then onto paper or other materials.

Application Range

Label Inks

Label offset printing inks are specialised inks used in offset printing for producing high-quality labels and packaging.

Laquers & Adhesives

Lacquers and adhesives in offset printing are materials used for coatings, finishes, and bonding in the printing process.

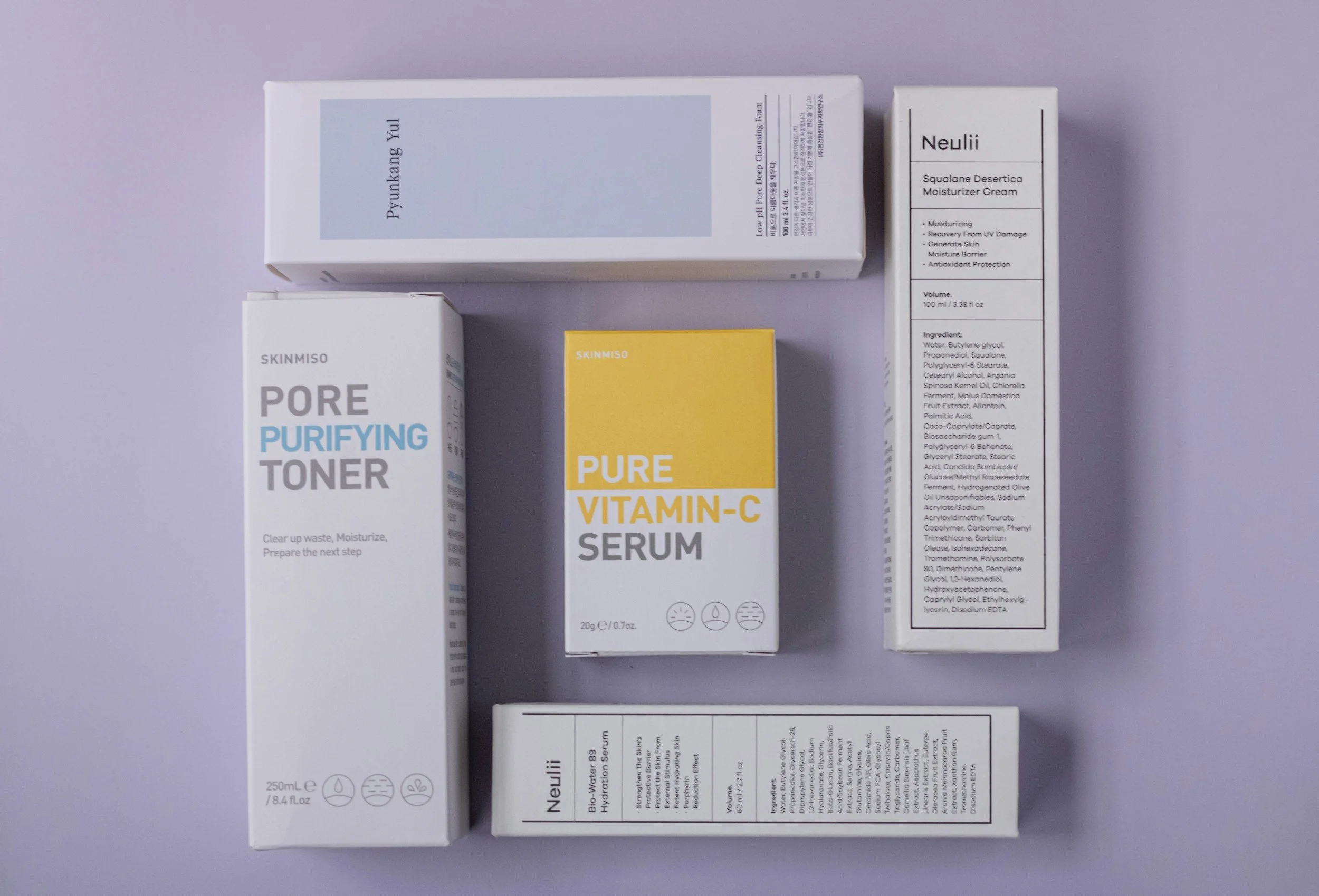

Packaging inks

Packaging offset printing inks are specialised inks used for printing packaging materials with high-quality

Commercial Inks

Commercial offset printing products are used for high-quality, large-volume printing in the commercial printing industry.

Metal Inks

Metal Decoration offset inks are specialised inks designed for printing on metal surfaces with high-quality results.

Offset Printing Blankets

Offset printing blanks are treated material used to transfer ink to rubber sheets for high-quality printing.

Rigid Plastic Inks

Rigid plastic offset printing inks are specialised inks for high-quality printing on rigid plastic materials.

UV Offset/Letterpress Inks

-

The UVALUX® U40 Ink Series is a next-generation UV ink system developed for high-speed letterpress and offset printing, offering excellent print quality, very low odour, and VOC-free performance—perfect for commercial and non-food packaging applications.

Key features:

UV-curable ink for offset sheet-fed, web-fed, and letterpress printing

Designed for high-speed presses with low misting for clean operation

Low-odour and VOC-free formulation for safer workplace conditions

Excellent adhesion and gloss on coated, uncoated, and plastic-coated paper

Compatible with overvarnishing, hot/cold foiling, laser printing, and thermal transfer

Available in 4-colour process, PSO, Pantone®, and Z base colour

Applications:

Direct mail

Forms

Folded cartons

Self-adhesive labels

End-use sector:

Commercial printing

Packaging

Non-food labelling

-

The UVALUX® U41 Ink Series is a low-migration, UV-curable ink developed for high-speed offset and letterpress printing—offering excellent adhesion, low odour, and food packaging safety, especially on paper-based substrates.

Key features:

UV-curable ink for sheet-fed, web-fed offset and letterpress printing

Low-migration and low-odour, ideal for food packaging

Optimised for paper, coated/uncoated, and plastic-coated substrates

VOC-free formulation with minimal misting at high press speeds

Suitable for overvarnishing, foiling, laser and thermal transfer finishing

Available in 4-colour process, PSO, Pantone®, and Z base colour systems

Applications:

Direct mail

Folded cartons

Labels

Forms

End-use sector:

Food-safe packaging

Commercial print

Non-food packaging

-

The UVALUX® U70 Ink Series is a UV-curable, VOC-free ink range designed for non-absorbent substrates, offering exceptional adhesion and low odour—making it ideal for demanding applications such as credit cards, packaging, and speciality labels.

Key features:

UV-curable ink for sheet-fed and web-fed offset printing

Optimised for film, metalised, and plastic-coated papers

Excellent adhesion and press performance on non-absorbent materials

Low-odour and VOC-free formulation

Supports hot and cold foiling, overvarnishing, and lamination (incl. credit card lamination)

Available in 4-colour process, PSO process, Pantone®, and Z base colours

Applications

Specialty packaging

Labels

Laminated items (e.g. credit cards)

End-use sector:

Non-food packaging

Commercial specialties

-

The UVALUX® U71 Ink Series is a low-migration UV-curable ink specially developed for food, cosmetics, and pharmaceutical packaging, offering excellent adhesion on non-absorbent substrates and full compliance with strict industry regulations.

Key features:

UV-curable ink for sheet-fed, web-fed offset, and letterpress printing

Designed for non-absorbent materials like film, plastic-coated and metalised paper

Low-migration and VOC-free, suitable for food and sensitive packaging

Glossy finish with strong adhesion and print clarity

Compatible with laminating, overvarnishing, and hot foiling

Conforms to Nestlé Guidance Notes and Swiss Ordinance 817.023.21

Available in 4-colour process, PSO, and Z base colour systems

Applications:

Flexible packaging

Folded cartons

Shrink sleeves

Self-adhesive labels

End-use sectors:

Food

Cosmetics

Pharmaceuticals

-

The UVALUX® U48 is a high-resolution UV ink for sheetfed and web-fed offset, delivering precision detail and vibrant colour reproduction across commercial print and packaging formats.

Key features:

Sharp dot definition for fine graphics and text

High colour strength and smooth laydown

Excellent curing and adhesion

Versatile across paper-based stocks

-

Item description

-

Item description

UV Flexo Inks

-

UVAFLEX® FCM Y81 is a low-migration UV flexo ink series formulated for direct contact food packaging, offering high colour strength, excellent adhesion, and safe compliance with stringent industry regulations—ideal for labels, folding cartons, and flexible packaging.

Key features:

UV-curable flexo ink for food-safe packaging and labelling

Low-migration and compliant with EU food packaging standards

Excellent printability, colour strength, and substrate adhesion

Suitable for overvarnishing, cold foiling, and lamination

Designed for paper, film, and foil substrates

Available in Pantone® and custom mixing bases

Applications:

Folding cartons

Flexible packaging

Self-adhesive labels

End-use sectors:

Food

Cosmetics

Pharmaceuticals

-

UVAFLEX® Y77 is a versatile UV-curable flexo ink series designed for non-food packaging and label applications, delivering high colour intensity, strong adhesion, and reliable performance across a wide range of substrates.

Key features:

UV-curable flexo ink for packaging and labelling

High colour strength and print consistency

Excellent adhesion on paper, film, and foil

Ideal for overprinting and finishing applications

Suitable for industrial and commercial packaging

Water-Based Flexo Inks

-

HYDROTEK YW is a high-performance, low-migration water-based flexo ink series designed for safe and vibrant printing on food packaging and labels. With excellent colour strength, high scratch resistance, and easy washability, it’s ideal for sensitive applications across various substrates.

Key features:

Water-based flexo ink system for food-safe packaging and labels

Low-migration and VOC-free for compliance with stringent food safety regulations

Strong adhesion and glossy finish with high scratch resistance

Prints on a wide range of substrates including coated, uncoated, thermal, metalised paper and film

Suitable for overvarnishing, hot foiling, and thermal direct printing

Available in Pantone® and Z Base Colour mixing systems

Conforms to Nestlé Guidance Notes and Swiss Ordinance 817.023.2

Applications:

Folding cartons

Flexible packaging

Self-adhesive labels

End-use sectors:

Food

Cosmetics

Pharmaceuticals

Electron Beam Offset Inks

-

The ESALUX E4 Ink Series is an advanced electron-beam (EB) curing offset ink system developed specifically for food-safe and odour-sensitive packaging. Free from photo-initiators and VOCs, this ink offers exceptionally low odour and migration—making it ideal for printing on cartonboard and flexible films used in food, cosmetics, and pharmaceutical packaging.

Key features:

EB-curing offset ink for web-fed applications

Initiator-free formulation with ultra-low odour and migration

VOC-free and food-compliant, ideal for sensitive end uses

Compatible with film, coated/uncoated paper, and plastic-coated substrates

Supports advanced finishing: overvarnishing, hot and cold foiling

High-gloss cured surface with excellent print fidelity

Available in 4-colour process, Pantone® base colours, and Z base colours

Approved under Swiss Ordinance 817.023.21 for food packaging

Applications:

Flexible packaging

Folding cartons

Self-adhesive labels

End-use sectors:

Food

Cosmetics

Pharmaceuticals

Waterless Offset Inks

-

The TORACUR W71 Ink Series is a low-migration UV-curable ink developed for waterless offset printing, offering exceptional image quality and safe performance for both food and non-food packaging—ideal for high-detail applications such as labels, customer loyalty cards, and promotional items.

Key features:

UV-curable (Mercury Vapour) formulation for waterless offset printing

Low-migration and VOC-free, suitable for food packaging

Wide press temperature range (22°–30°C) with minimal tonal value increase

Excellent adhesion on paper, film, and metalised substrates

Compatible with thermal transfer, thermal direct, and overvarnishing

Available in 4-colour process, PSO process, Pantone®, and Z base colours

Complies with Nestlé Guidance Notes on Packaging Inks

Applications:

Folding cartons

Flexible packaging

Self-adhesive labels

Specialty items like loyalty cards and mousepads

End-use sectors:

Food

Cosmetics

Pharmaceuticals

Rigid Plastic Offset Inks

-

The ROLID® RV Ink Series is a heat-drying (IR) ink system formulated for indirect letterpress (dry-offset) decoration of preformed plastic containers such as cups, buckets, and lids, offering excellent resistance to a wide range of fillings and maintaining print quality under demanding conditions.

Key features:

IR and solvent-based curing for fast, consistent drying

Optimised for dry-offset printing on preformed plastic items

High scratch resistance and glossy finish for durable container use

Outstanding adhesion on film and plastic substrates

Not suitable for overvarnishing; best for direct-use container applications

Available in Z Base Colours and Pantone® matching systems

Compliant with select food-contact and metal decoration standards

Overprint Lacquers

Enhance surface appearance and protection with gloss, matt, relief, or release finishes—available for both food and non-food packaging.

Gloss, Matt & Special Effect Lacquers

These UV-curable lacquers are designed to enhance surface finish, protection, and visual appeal—available in gloss, matt, and specialty variants for food and non- food packaging. Several FCM (food contact material) formulations offer low migration for safe use in sensitive packaging.

-

These UV-curable gloss lacquers deliver high shine and print protection for offset applications, boosting durability on packaging and label surfaces.

Key features:

Available in multiple gloss levels (regular and FCM low-migration versions)

Protects against scratches, abrasion, and scuffing

Suitable for paper, board, film, and foil

VOC-free and fast-curing

-

Low-migration versions of the gloss lacquer, formulated for direct food contact packaging with regulatory compliance.

Key features:

FCM-certified for food-safe applications

Retains gloss and protection without migration risk

UV-curable and VOC-free

Compatible with flexible and rigid packaging formats

-

Ultra-matt lacquer options (including FCM-safe) provide a modern, velvet finish for premium packaging and label applications.

Key features:

Gloss levels range from deep matte to soft sheen

Available in FCM-compliant low-migration versions

Retains anti-scratch and anti-fingerprint properties

Quick curing and surface protection

-

High-performance UV lacquers with both gloss and ultra-matt finishes, designed for excellent surface durability and aesthetic flexibility.

Key features:

Gloss or ultra-matt options to match branding needs

Excellent mar and chemical resistance

UL-7M210FCM is food-safe for packaging direct contact

Fast UV cure with smooth finish

-

Specialist lacquer that creates a raised, textured relief finish for tactile visual effects on printed labels and packaging.

Key features:

Builds volume for embossed or relief texture

Excellent clarity and structural strength

Designed for precise on-press application

UV-curable and quick-setting

-

Formulated to provide clean release layers, these lacquers enable effective cold foil or masking processes without compromising adhesion.

Key features:

Provides temporary non-stick layers for cold-foil processes

UV-curable and press-stable

Works with both UVAFLEX and UVALUX UV ink systems

Ideal for multi-layer press applications

Relief & Release Lacquers

Designed for tactile finishes and peel-off effects, these lacquers create raised (relief) surfaces or function as temporary coatings in multi-layer production. Ideal for high- impact print applications and advanced label production.

-

Specialist lacquer that creates a raised, textured relief finish for tactile visual effects on printed labels and packaging.

Key features:

Builds volume for embossed or relief texture

Excellent clarity and structural strength

Designed for precise on-press application

UV-curable and quick-setting

-

Formulated to provide clean release layers, these lacquers enable effective cold foil or masking processes without compromising adhesion.

Key features:

Provides temporary non-stick layers for cold-foil processes

UV-curable and press-stable

Works with both UVAFLEX and UVALUX UV ink systems

Ideal for multi-layer press applications

Primers are applied before ink or foil to promote adhesion, prevent delamination, and prepare difficult substrates. These UV formulations are available in both standard and low-migration (FCM) versions.

Primers

-

UVAFLEX® YL-5P000 is a UV-curable primer developed to improve ink adhesion and printability on challenging non-food substrates, particularly aluminium-coated materials. Known for its high reactivity, it also supports additional processing like glueing and hot-foil stamping.

Key features:

Enhances ink adhesion on difficult surfaces

High reactivity for efficient curing

Compatible with hotfoiling, glueing, and thermal transfer

Designed for film and metallised paper

Ideal for brochures, folded boxes, and self-adhesive labels

-

High-gloss lacquer with strong adhesion, ideal for non-food brochures, packaging, and label applications.

Also suitable as a primer for difficult substrates, UVALUX® UL-5P100 delivers excellent surface finish and versatility for further processing such as hot foiling and thermal transfer.

Key features:

• UV-curable with high reactivity

• Glossy finish with excellent adhesion

• Acts as both overprint lacquer and primer

• Suitable for a wide range of substrates including film and coated paper

• Non-food formulation, VOC-free and mineral oil-free

UV laminating adhesives are used to bond protective or decorative films onto printed surfaces, providing added durability and visual enhancement. These adhesives ensure strong lamination for flexible packaging and carton applications.

Laminating Adhesives

-

OPTIFLEX® U06208832 is a high-performance UV-curable adhesive designed for laminating printed substrates in packaging applications.

Offering strong bond strength and excellent clarity, it is ideal for demanding multi-layer constructions and specialty packaging.

Key features:

• Excellent adhesion for film-to-paper or film-to-film laminates

• Fast UV curing for efficient production

• High transparency – minimal visual impact on printed graphics

• Suitable for flexible packaging and carton applications

• Press-stable and easy to handle on high-speed lines

-

UVAFLEX® U0805LM is a low-migration (LM) UV adhesive formulated for food packaging applications requiring stringent safety and performance.

It delivers reliable lamination with minimal migration, meeting key packaging compliance standards.

Key features:

• Low migration formulation – ideal for indirect food contact

• Excellent adhesion to challenging substrates

• VOC-free, UV-curable for high-speed applications

• Maintains clarity and print fidelity

• Perfect for self-adhesive labels and folding cartons

-

UVAFLEX® U0803LM is a specialised low-migration UV laminating adhesive engineered for demanding packaging workflows.

It offers strong bond integrity, food-compliance, and clean processing across a wide range of substrates.

Key features:

• Food-safe LM formulation for sensitive applications

• Reliable bonding on coated, metalised, and synthetic substrates

• UV curing for efficient, heat-free processing

• Suitable for flexible packaging, shrink sleeves, and more

• Designed for performance and safety in regulated markets

-

BIRKAN blankets are engineered for consistent ink transfer, edge definition, and long service life across sheetfed and web offset presses. Suitable for a range of substrates and compatible with both UV and conventional inks.

Key features:

Precision ink transfer for high print quality

Resilient surface for extended blanket life

Suitable for both UV and conventional systems

Options for metal, plastic, and paper substrates

Available for sheetfed and web offset setups

-

Underpacking materials help optimise blanket height and pressure uniformity, ensuring consistent print density and register accuracy. These solutions are essential for maintaining high-quality results across long print runs.

Key features:

Uniform pressure distribution under blanket

Prevents overcompression and maintains dot fidelity

Available as foils, sheets, or dedicated underpacking blankets

Compatible with all major offset press configurations

Easy to install and replace

Offset Printing Blankets

Let’s work together

Let our experts analyse your current workflow and recommend the perfect print solution for your business.

See the Kissel+Wolf Difference Today

Join over 500 Australian printers who trust Kissel+Wolf for premium screen printing inks that deliver vibrant results, reliable performance, and global brand compliance. From eco-friendly water-based options to specialty and plastisol inks, we’ve got every print covered.