UV Curable Solutions

Mutoh XpertJet 461UF

483 × 329 mm print area, handling media up to 150 mm thick

CMYK + White + Varnish inks with instant UV-LED curing—scratch-resistant and vibrant

Local Dimming Control technology for matte-gloss texture effects in one pass

Optional vacuum table for depth control and heavier substrates

Bundled with VerteLith™ RIP and FlexiDesigner MUTOH Edition software

Compact A3+ UV‑LED flatbed printer for direct-to-object printing

The 461UF is a small-footprint UV printer offering high-resolution, multi-layer printing with colour, white, and varnish on rigid and flexible substrates—perfect for personalised merchandise, small signage, and gift items.

Mutoh XpertJet 661UF

Larger A2+ UV‑LED flatbed printer built for industrial-scale versatility

The 661UF expands printable area and throughput, enabling high-quality multi-layer printing with durable inks and robust automation—ideal for larger promotional items, signage components, and ADA-compliant Braille output.

483 × 329 mm print area, handling media up to 150 mm thick

CMYK + White + Varnish inks with instant UV-LED curing—scratch-resistant and vibrant

Local Dimming Control technology for matte-gloss texture effects in one pass

Optional vacuum table for depth control and heavier substrates

Bundled with VerteLith™ RIP and FlexiDesigner MUTOH Edition software

Mutoh XpertJet 1462UF

High-capacity flatbed UV‑LED printer for medium-format, production-grade output

The 1462UF delivers large-format capability (55″×27″ bed) and multi-layer printing with ADA-compliant Braille, 2.5D textures, and high-speed curing—perfect for high-mix, high-volume industrial applications.

1,420 × 700 mm print area; supports media up to 150 mm thick and 50 kg/m² density

Two 4″ UV-LED lamps and staggered dual print heads (CMYK + White/Varnish) for two-layer prints

Four-zone magnetic vacuum table with jig points for flexible media set‑up

Auto Nozzle Check, Nozzle Area Select, and Local Dimming technology ensure uptime and finish quality

Bundled with VerteLith™ RIP and FlexiDesigner MUTOH Edition software

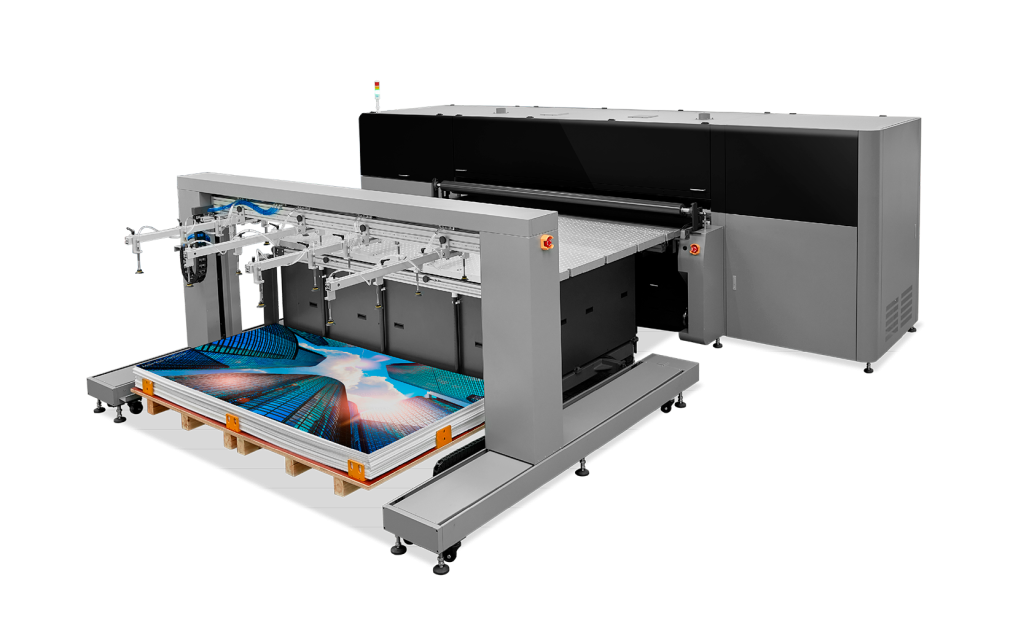

Handtop UV Flatbed Printers

Versatile flatbed UV printing for rigid substrates of all shapes and sizes

The Handtop UV flatbed series is designed for high-performance direct-to-substrate printing onto foam PVC, corflute, screen board, wood, glass, composite panels and more. Available in multiple bed sizes and configurable with Ricoh or Kyocera industrial printheads, the Handtop range offers flexibility, speed, and exceptional print quality across a wide array of applications.

Available Sizes:

HT1610UV: 1.6 m × 1.0 m

HT2512UV: 2.5 m × 1.22 m

HT3020UV: 3.05 m × 2.05 m

Printhead Options:

Ricoh Gen5: Durable and reliable with excellent grey scale capability

Kyocera: Ultra high-speed industrial heads for demanding production environments

Key Features:

Direct printing onto rigid and flat sheet materials up to 100 mm thick

Configurable ink sets: CMYK with optional White and Varnish for multi-layer and textured effects

High-resolution output with smooth gradients and vibrant colour reproduction

Precision vacuum bed and anti-collision sensors for safe, stable printing

UV-LED curing technology for fast-dry, durable prints on heat-sensitive substrates

Kissel+Wolf Australia distributes and services the full Handtop UV Flatbed range across Australia and New Zealand, with full technical support and installation available.

Handtop UV Hybrid Printers

Flexible hybrid UV printing for both roll and rigid media

The Handtop Hybrid UV printer series is designed for businesses needing the versatility to print on both flexible roll media and rigid sign substrates. With support for foam PVC, corflute, screen board, and composite panels, this printer range combines precision, speed, and media flexibility. Available in multiple widths and with your choice of Ricoh or Kyocera printheads, the Handtop Hybrid is built for performance-driven environments.

Available Widths:

HT1600UV: 1.6 m

HT2500UV: 2.5 m

HT3200UV: 3.2 m

Printhead Options:

Ricoh Gen5: Reliable with excellent greyscale capability for everyday production

Kyocera: High-speed industrial printheads for ultra-fast output and durability

Key Features:

Seamless switch between roll-to-roll and flat sheet media printing

Compatible with a wide range of materials including vinyl, film, foam PVC, corflute, and aluminium composite panels

Configurable ink options: CMYK with optional White and Varnish for multi-layer and textured print effects

Anti-collision sensor system for safer media handling

Industrial-grade UV-LED curing for immediate, durable finishes

Kissel+Wolf Australia distributes and supports the full range of Handtop Hybrid UV printers across Australia and New Zealand with installation, service, and expert support.

Handtop Roll-to-Roll UV Printers

High-speed wide-format UV printing for flexible roll media

The Handtop Roll-to-Roll UV series is engineered for continuous, high-volume printing onto a wide range of roll media including PVC banner, backlit films, mesh, and textile signage. With options up to 5 metres wide and industrial Kyocera or Ricoh printheads, this range delivers exceptional speed, sharpness, and production reliability—perfect for indoor and outdoor signage applications.

Available Widths:

HT3200UV: 3.2 m

HT5000UV: 5.0 m

Key Features:

Designed for uninterrupted, high-speed roll media printing in demanding environments

Compatible with PVC banner, mesh, backlit film, vinyl, and textile signage

Configurable in CMYK with optional White and Varnish for enhanced image effects and layering

Multi-row head options for increased speed and output capacity

UV-LED curing system ensures fast-dry, durable results across flexible substrates

Printhead Options:

Kyocera: Ultra high-speed output with multiple-row head configurations for maximum productivity

Ricoh Gen5: Consistent, high-quality performance and cost-effective durability

Kissel+Wolf proudly distributes and supports the full Handtop Roll-to-Roll UV range throughout Australia and New Zealand, offering installation, training, and ongoing service.

Handtop HTA 2500 Robo Printer

Key Features:

Robotic roll loading/unloading system for seamless automated operation

2.5 m print width accommodating large-format media up to industrial dimensions

UV‑LED curing for instant, durable results on flexible substrates

Optional Ricoh or Kyocera heads for configurable speed and quality performance

Front and rear vacuum table zones optimise media alignment and stability

Automated precision roll-fed UV printing solution with robotic media handling

The HTA 2500 Robo combines Handtop’s wide-format UV LED printing technology with an advanced robotic loader for consistent, unattended production. Perfect for busy production floors, it maintains high quality and precision without manual intervention.

Kissel+Wolf Australia offers full distribution, installation, and support across Australia and New Zealand for the HTA 2500 Robo.

Let’s work together

Let our experts analyse your current workflow and recommend the perfect print solution for your business.